Organic Solar Cell (OSC)

1.Organic Light-Emitting Diode (OLED) | 2.Organic Field-Effect Transistor (OFET) | 3.Organic Laser Diode (OLD) | 4.Organic Solar Cell (OSC)

Organic Solar Cell (OSC)

Now, we need concrete actions to solve environment and energy problems, and the importance of photovoltaic generation has been increasing. Because organic thin-film solar cells can be fabricated by low-temperature process, the cost for fabrication is less than that for conventional silicon solar cell. Furthermore, because they are light weight and flexible, there is a possibility that they will be used as general power-generation devices

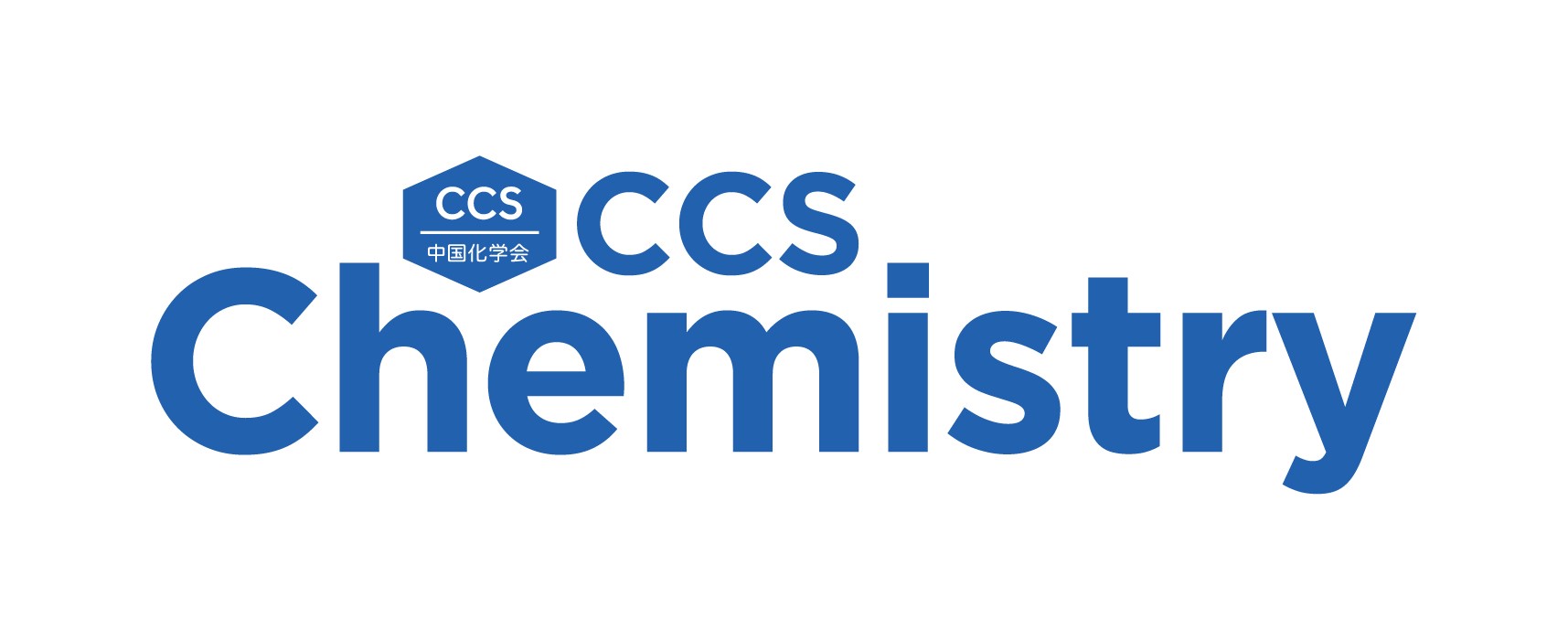

Fundamental Structure of OSC

Organic thin-film solar cells using low-molecular-weight materials are fabricated by vacuum deposition. First, organic materials having p- and n-type conductivities are successively deposited on a transparent electrode, and then, a metal electrode is deposited on them. The mechanism of electrical power generation in OSCs can be understood as an opposite process of emissions in OLEDs. Sunlight is absorbed by organic layers in OSC, and excitons generated by light absorption are dissociated to electrons and holes at the interface between p- and n-type organic layers. The electrons and holes are collected at the upper and lower electrodes, respectively, and electricity is generated. Furthermore, it is known that power conversion efficiency is improved by insertion of an electron transport layer.

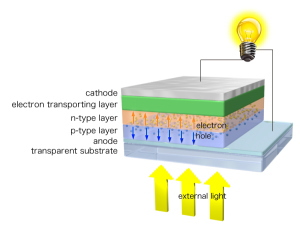

Bulk Hetero-Junction

A device structure with bulk hetero-junction is one of the most famous structures of OSCs. Because the interface between p- and n-type materials fabricated by co-deposition has a large area, exciton dissociation efficiency become higher and power conversion efficiency is improved. By controlling the ratio of the amounts of two co-deposited materials and the thickness of the layer, high-performance devices can be fabricated. However, details of the mechanism are not completely clear. Fundamental researches to elucidate it are still needed.